When learning a foreign language, a common recommendation is to immerse yourself in the country and the culture of that language. The same can be said for a product. If you really want to understand a product, you need to understand its origin, the raw materials, the manufacturing and distribution processes, and most importantly, the product’s application. In that vein, I recently accepted an invitation from Tile of Spain USA to participate in its Passport to Creativity Tour 2024 for a full immersion into the world of Spanish designed and manufactured tile in Valencia, Spain, the heart of the Spanish tile industry.

The event included a guided architectural tour of the city and its many landmarks; tours of both old-school and fully automated tile manufacturing plants and exquisitely curated showrooms; a private tour of the recently opened Centro de Arte Hortensia Herrero contemporary art museum in a renovated 14th century building; and two full days at Cevisama, the annual trade show (now in its 40th year) where manufacturers of tile, plumbing fixtures and allied bathroom products showcase their latest creations. The tour group was comprised of four architects and designers, five industry press professionals, one influencer, the travel host and photojournalist of design-travel show “The Design Tourist,” a bilingual industry consultant from North America and two U.S.-based members of the Tile of Spain’s public relations team. It was a dynamic group, to say the least.

The History of Tile

To understand how the Spanish tile industry began and continues to flourish today, it’s important to turn back the pages of history. The earliest known examples of manufactured tile are Egyptian, dating back to 4,000 BC. Several cultures including the Assyrians, Babylonians and the Islamic Empire are also credited with cultivating tile production for functional and decorative use in residences, houses of worship and construction materials such as roof tiles, gutters and irrigation. As the Islamic Empire expanded beyond Mesopotamia (now the Middle East) into Europe, so did its culture and crafts, including tile.

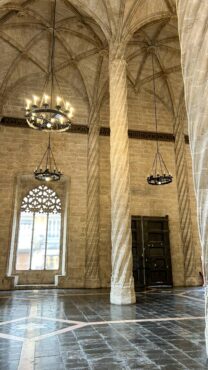

Valencia is one of the oldest cities in Spain, having been founded as a Roman colony in 138 BC and ruled until 476, when the hands of the Christian Visigoths took power until they were defeated by the Arab Empire, the Moors from Northern Africa, in the early 8th century. The Moors brought their tile traditions to Valencia and are credited with establishing the vitrified ceramic tile tradition, along with the use of colored glazes and intricate patterns, that excluded any representation of living beings such as people or animals, referred to as Zellige. Though the Moors were expelled from Spain in the 13th century, their decorative tile styles are still in vogue today.

A Few Tile Basics

Tile has stood the test of time because of its many attributes of being durable, hygienic, nonflammable, resistant, versatile, sustainable and infinitely flexible in its application as a decorative material. Before diving into trends observed at Cevisama, let’s cover some basic information. Below are the five most common types of tiles produced today.

Ceramic tiles are made with white or red clay, talc, sand, feldspar, dolomite and calcite. The clay is “punched” (machine cut) into a desired shape such as a square or rectangle, baked (fired) at a high temperature to make the soft clay dense and durable. The tile is then glazed with a mixture that may include silica and metal oxides depending on the desired finish, matte or gloss, then baked again at a lower temperature to ensure a good bond and a consistent finish of the glaze. Ceramic tiles are typically used on interior walls but depending on the fabrication process may be used on interior floors, exterior walls and exterior walkways.

Porcelain tiles are made from a finer white clay, formed using a high-pressure compression and fired at a higher temperature than ceramic tiles. The combination of high pressure and temperature create these tiles’ highly impervious quality, which makes them particularly suitable to high-moisture areas such as showers and bathroom floors as well as high traffic interior floors and exterior cladding. Porcelain tiles have a pattern or color “glazed” on the surface with the help of an ink jet printer. This makes them more cost effective than a color-through-body porcelain tile, which has the primary glaze color mixed into the clay body of the tile as well as the decorative pattern and glaze on the surface of the tile.

Cementitious tiles are comprised of a mixture of sand, cement, color pigment and a marble powder that is poured into a mold, backed by a dry concrete mixture, and then compressed under 2,000 pounds of pressure. They typically have a matte, unglazed finish, making them a potential candidate for a penetrating sealer to prevent staining. The durability of cementitious tiles makes them a good installation candidate for both indoor and outdoor applications on floors and walls.

Extruded tiles are made by extruding a base of ceramic or porcelain glass through a mold to a desired thickness, with a reduced weight and cost. Think meat grinder or spritzer cookies. The “deck” boards by Hacon, for example, are approximately 1-inch thick but have multiple hollow chambers running the length of the boards to reduce the shipping and handling weight and increase the ease of installation.

Glass tiles are produced by fusing multiple sheets of glass at 1,500 F in a kiln to create a single piece. They are nonporous and frost-resistant, which makes them excellent candidates for indoor and outdoor wall, fountain, pool and shower applications (most glass tiles are not rated for floor installations). Glass tiles are more rigid than ceramic, porcelain or cementitious tiles and require more handling in the manufacturing (mesh or paper backing is typically applied to glass mosaic tiles after the tiles have been fired), shipping and installation, which is one reason they are more expensive per square foot than other types of tiles.

Natural stone tiles (marble, granite, limestone, travertine) are cut from quarried stone slabs or fabricated from stone slab off-cuts. These tiles are not fabricated in a factory or fired in a kiln.

Like any product or profession, there is terminology specific to tile manufacturing and tile installation. The American National Standards Institute (ANSI) is a nonprofit entity that oversees the development of voluntary consensus standards for products, including tile. ANSI standards address the porosity, slip resistance, approved installation application and other related tile characteristics. These standards can help mitigate issues surrounding tile purchase and installation that may lead to poor installation (cracking, lipage, etc.) or safety issues. Every tile product has a specification sheet that summarizes its ANSI qualifications.

Highlights from Cevisama

Tile of Spain, the marketing arm of the Association of Spanish Manufacturers of Ceramic Tile (ASCER), has been co-sponsoring Cevisama for decades. ASCER has over 100 manufacturing members who are held to the highest standards of ethical and sustainable manufacturing and labor practices, efficiency and more.

Cevisama 2024 had 838 exhibitors and approximately 91,000 attendees. The show floor was bursting with beautiful new designs and several notable updates of established favorites. With so many beautiful tiles, choosing the standout trends for 2024 was hard, but here are the highlights.

Bigger is better: Ultra-thin, large-format porcelain slabs (sintered stone) are getting bigger (9 feet long) and more realistically mimicking quarried stone and wood looks. This is due to technological advancements in the ability to “layer” the glazing design imaging and coloration with ink jet printing. The net result is that you can “feel” the grain in the wood-look tiles and create reliefs in the veins of the quarried stone-look tiles.

Economic reduction in carbon footprint: Taking shipping and end-user installation costs into consideration, many Spanish tile manufacturers are creating structural (high-relief) tiles that mimic the look of dry stack stone and flagstone to meet the increasing demand for outdoor entertaining spaces but in a much lighter-weight format. What appears to be several pieces of stone are actually 12-by-22-by-1/2-inch tiles notched on either short side so they fit together like puzzle pieces and can be cut without compromising the realistic stone look.

Customized looks: It’s all about individual expression through customization. Mix-and-match tile families provide a dynamic custom look, with solid, patterned and high-relief tile offered in a curated color collection, allowing consumers and designers to create unique combinations that reflect individual style.

I can’t believe… it’s tile: A technique called “third fire” renders tiles with an ethereal and tactile surface when multiple layers of glaze are fired individually. Perfect for an accent wall or countertop to maximum effect.

Alignment with clean, contemporary, biophilic design: How can an inert object like tile evoke nature’s ability to create a sense of calm and wellbeing? Tile manufacturers such as Living Ceramics create large-format porcelain tiles with natural, sensorial, minimalistic finishes using a fabrication prescription of graphics, digital glazing and printing that is synergistic with biophilic design. These tiles also create a low-maintenance surface for walls and floors.

Natural looks: From the dramatic to the subtle, to an ’80s retro look, porcelain tiles are mimicking earthy, geological, quarried stones better than ever. Travertine is baaaccckk! The porcelain travertinesque tile from Gya Fores is anything but dated. It’s low maintenance and available in supersized panels for cladding for shower walls (and more) and with a finish that is more consistent yet natural looking than a quarried travertine.

Tiles with texture: Ceramic and porcelain tiles are incorporating a variety of textures for indoor and outdoor application. This is in line with the fashion and furnishing trends where you will find ribbed clothing fabrics, high-nap embossed leathers, fluting and 2-dimensional in-wall cladding and furnishing, etc. An example is the snakeskin finish tile by Aprici — subtle yet dramatic.

With all this newfound tile knowledge, consider how you can use this expressive, durable and sustainable product in your next project. For more inspiration, visit Valencia Spain and the Museo National de Ceramica at cultura.gob.es/mnceramica/en/home.html.